Services & Technical

Expertise

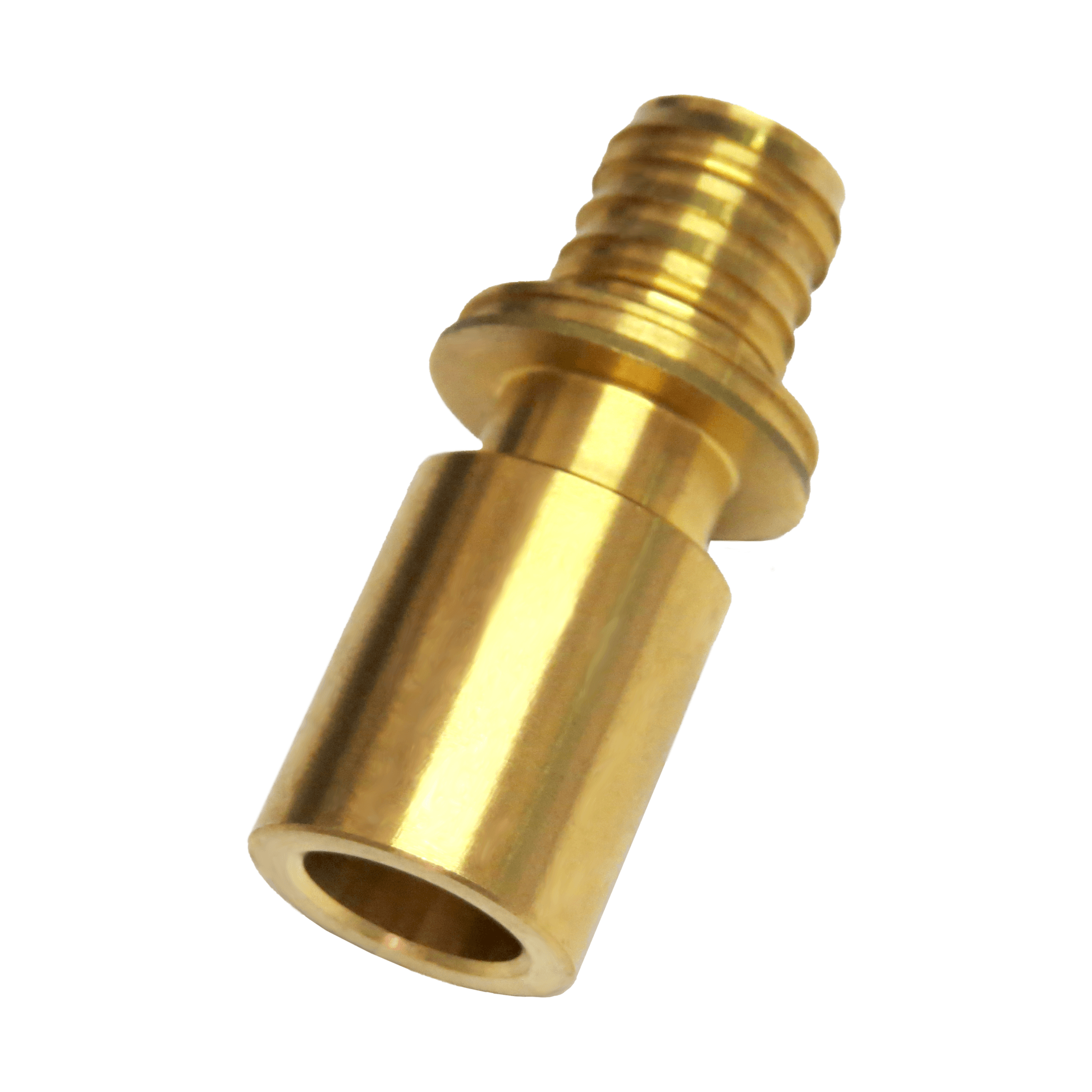

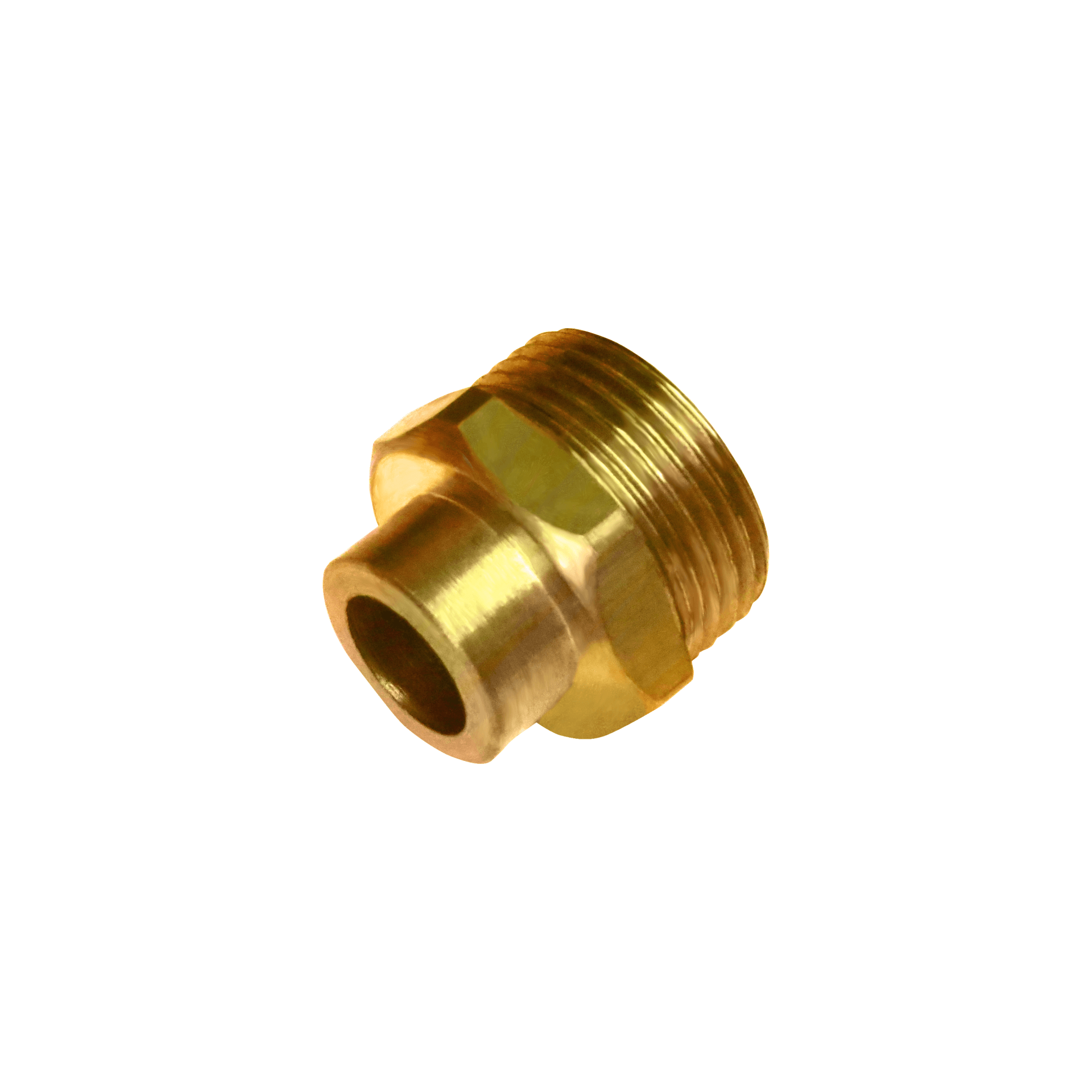

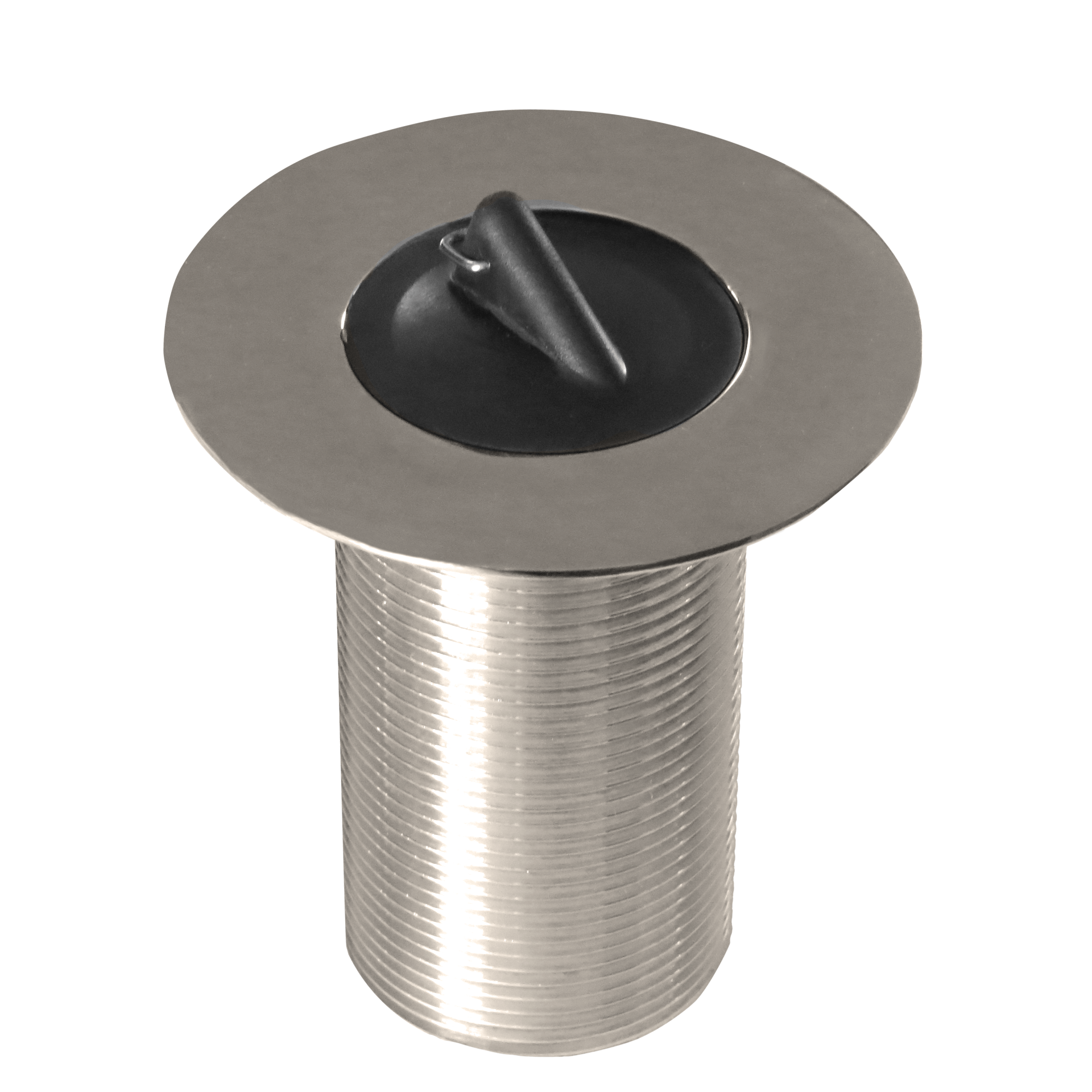

- Alloys / Brasses

- Casting & Forging

- Brass Machining

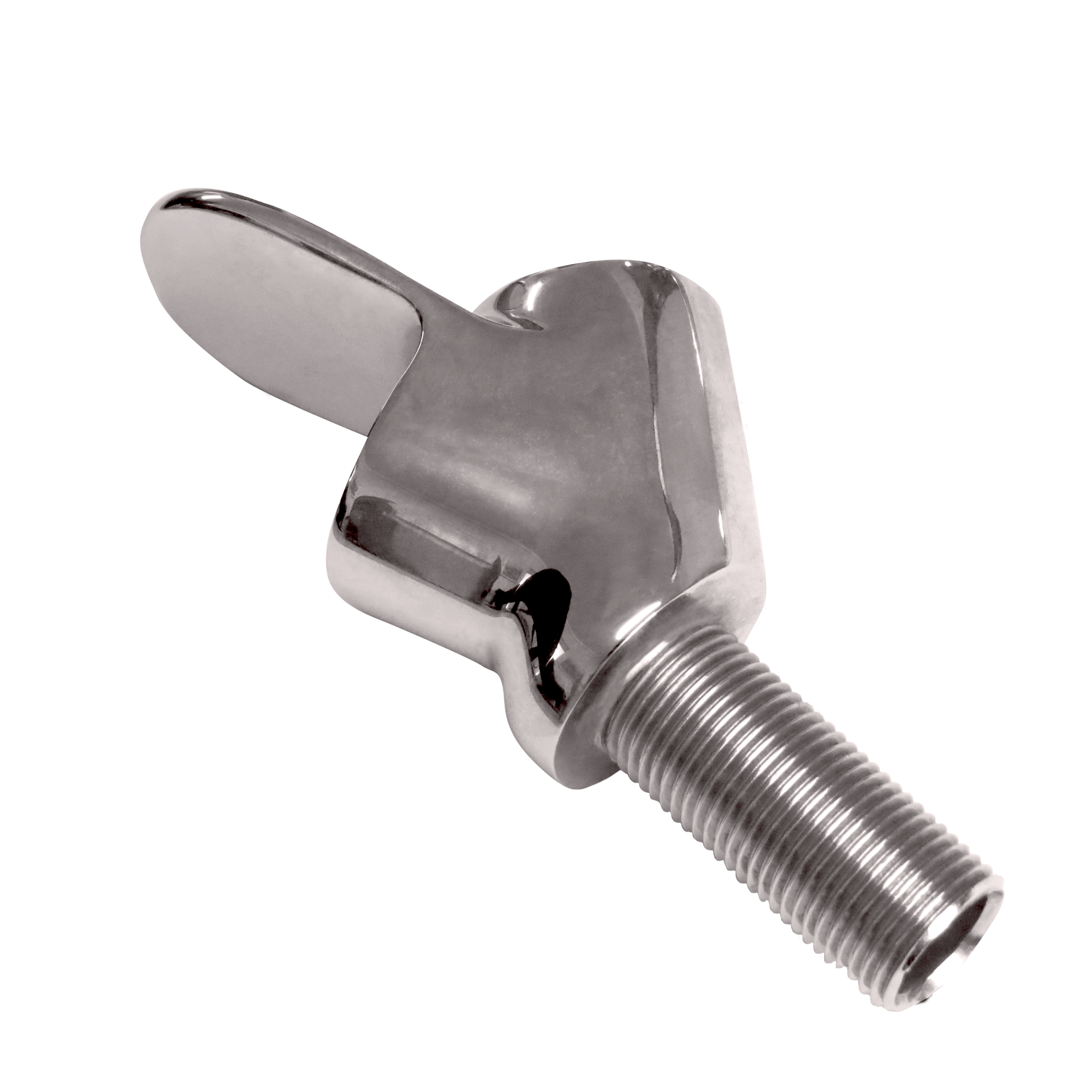

- Plating & Finishing

Contact us about development or new brass products.

Providing optimal solutions to our clients. The company also provides completed and assembled products, as well as parts, to other factories.

EXIPRO Alloys / Brasses

EXIPRO produce products from, and has access to the complete range of, alloys from its in-feed material alloy specialist Non-Ferrous metals

FAQs

Got a question about EXIPRO Alloys / Brasses? We’re here to help.

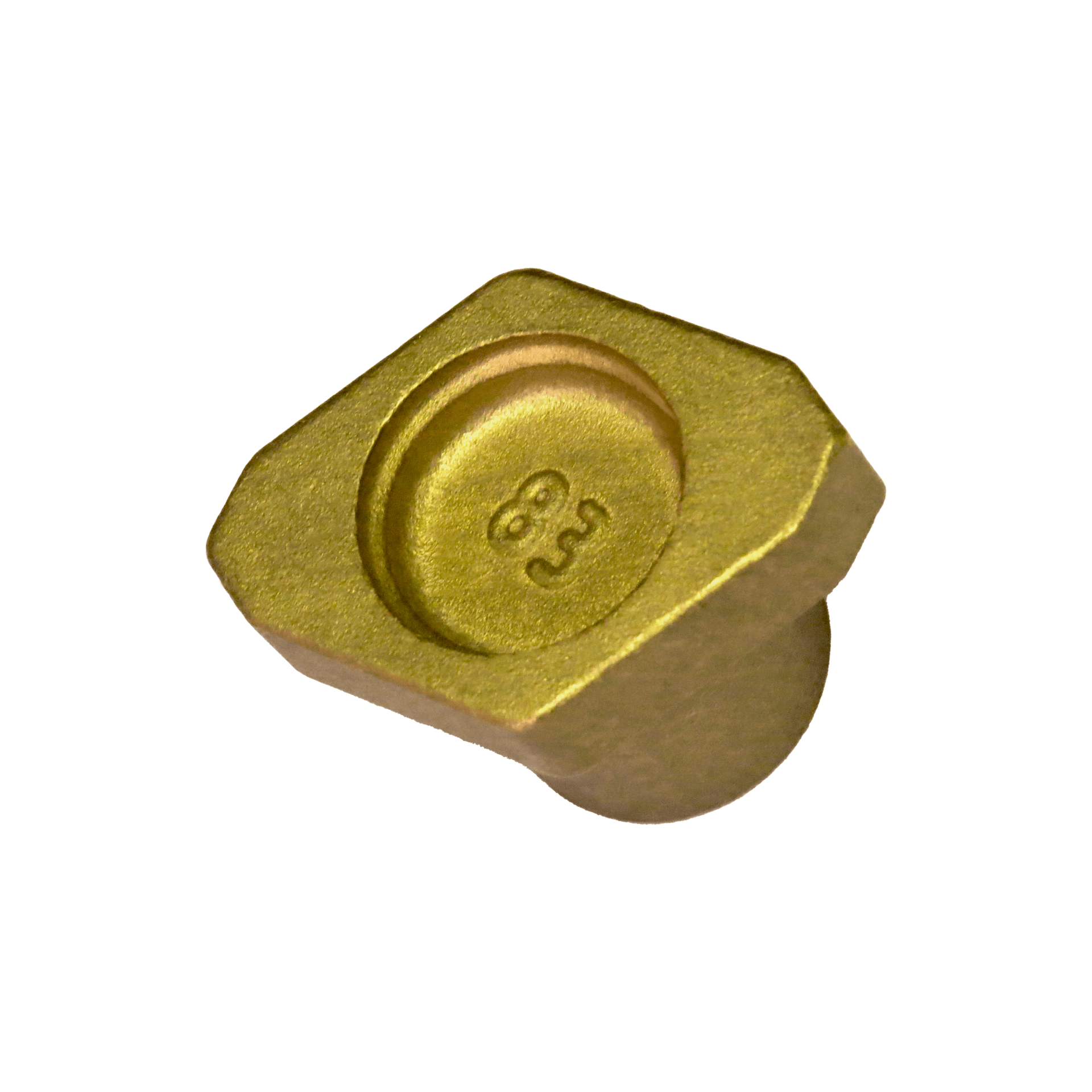

DZR BRASS Dezincification of brass is a critical aspect of the fitness for purpose (quality) of plumbers fitting that is in contact with water. The risk and rate of dezincification increases with water hardness and the acidity or alkalinity of water away from a PH of 7. Dezincification is the name given to the corrosion of brass. Dezincification resistant brass, or DZR brass, (something designed CR or DR) is the name given to brass that has exceptional resistance to this corrosion. The resistance is imparted by the adherence to SABS specifications for chemical composition and careful process controls. In order to be called DZR brass each batch must pass an ISO 6509 dezincification resistance laboratory test. In South Africa the use of DZR brass for components of brass plumber’s fittings that are in contact with water is national law. Building inspectors are being trained to demand the removal of plumber’s brassware that does not conform to statutory law.

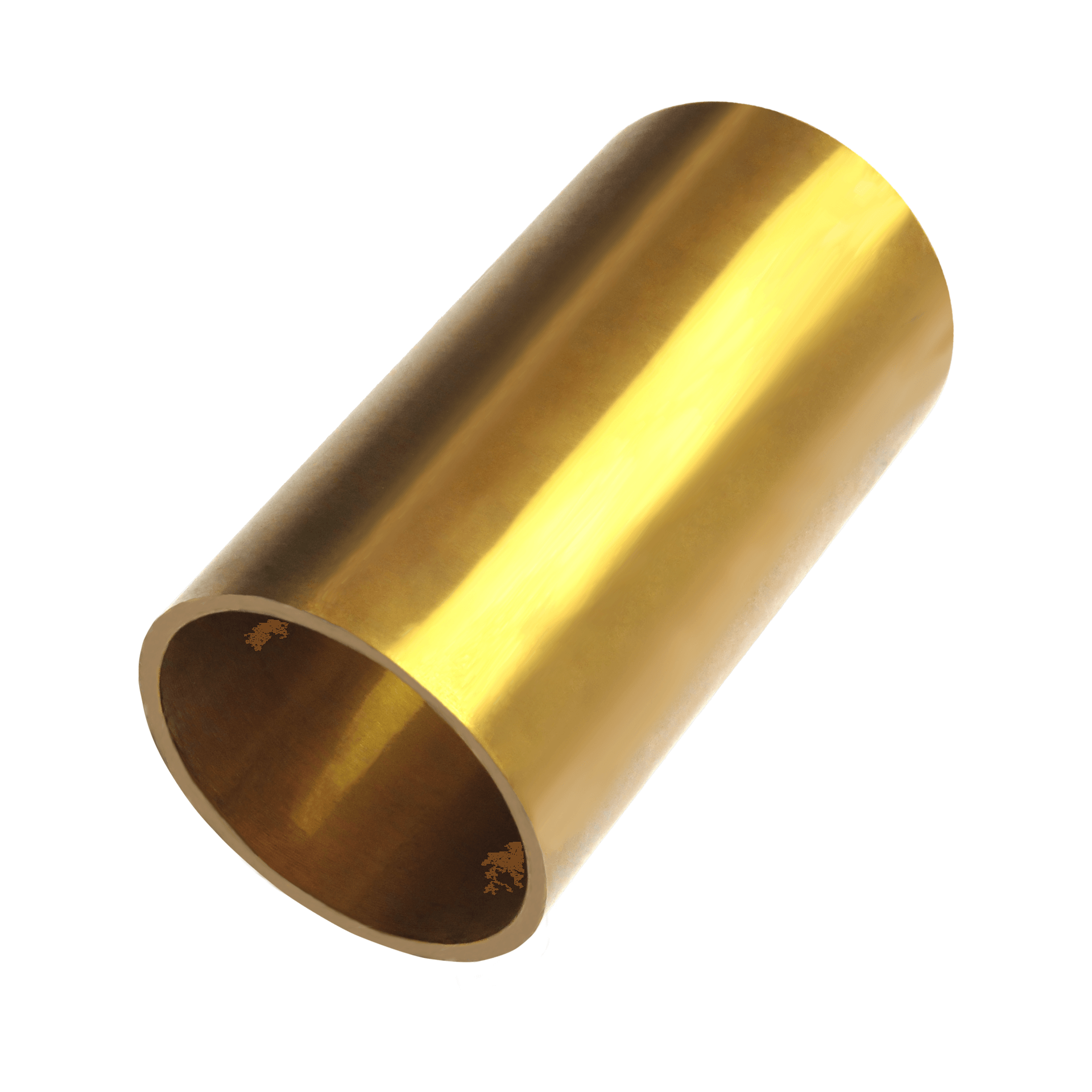

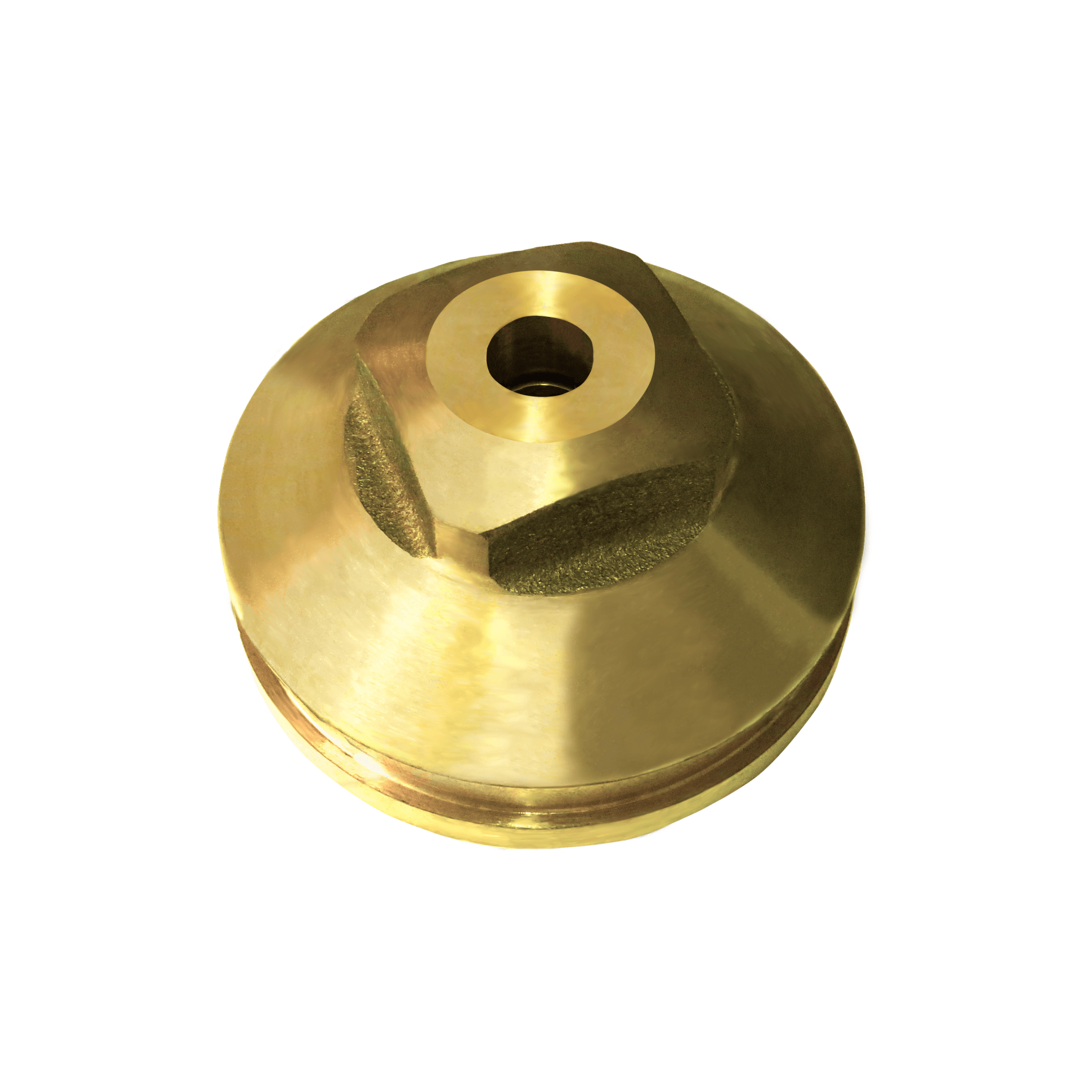

EXIPRO Casting & Forging

EXIPRO has extensive experience in assisting customers in choosing between casting and forging and always openly discusses the pros and cons with customers.

FAQs

Got a question about EXIPRO Casting & Forging Methods? We’re here to help.

EXIPRO Brass Machining

EXIPRO has a wide variety of machining equipment in Standard and CNC Turning, Drilling, and Milling configurations as well as a variety of specialty combination machining equipment to process larger volumes in one operation.

FAQs

Got a question about EXIPRO Machining? We’re here to help.

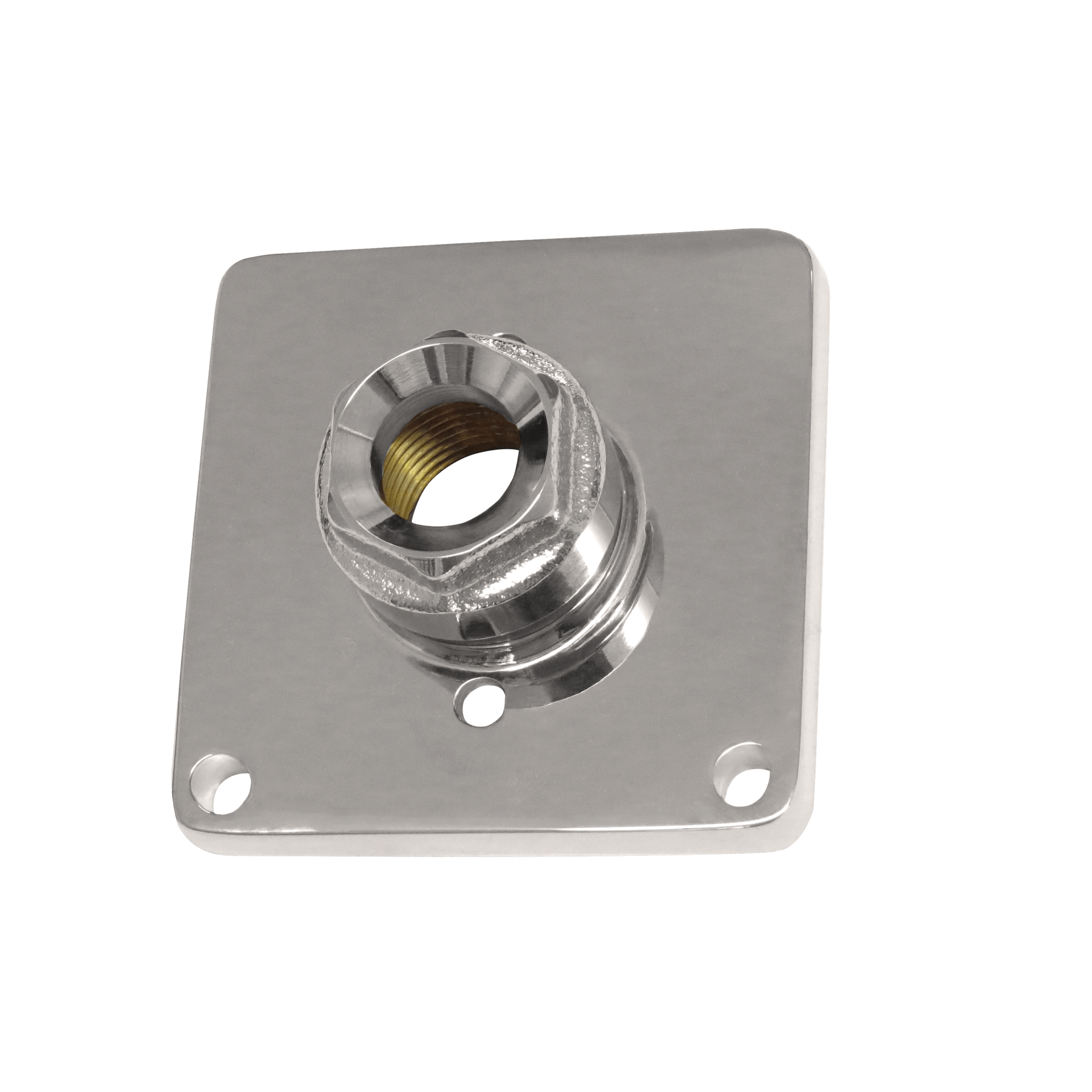

EXIPRO Plating & Finishing

EXIPRO provides a range of plating & finishing services and products. EXIPRO has 30 years of experience in finishing an array of parts in a huge variety of shapes and EXIPRO provides this service as a stand-alone service to many customers.

FAQs

Got a question about EXIPRO Plating & Finishing? We’re here to help.

CHROME-PLATING BRASS Brass is a versatile, binary alloy made from zinc and copper that carries multiple advantages — it's affordable, low-friction and highly machinable, and it also maintains good heat and electrical conductivity. You can utiliSe brass in various ways, but you can also add to its overall finish and properties with multiple plating processes.